EMAIL

EMAIL

09. May. 2025 — Cubic has successfully exhibited its latest innovations at SENSOR+TEST 2025 international trade fair, showcasing how its smart technologies and sensing solutions empower the six key application fields, including oil & gas, semiconductor manufacturing, medical & healthcare, automotive electronics, HVAC & refrigeration, and heating boiler & furnace.

As the leading trade fair for sensor, measuring and testing technology, SENSOR+TEST, took place in Nuremberg from 6-8 May 2025. Numerous exhibitors from all around the world presented their advancement at the SENSOR+TEST. Visitors can discover the latest developments and technologies, and learn about the many industrial trends in sensor and measurement technology in detail. The event served not only as a platform to highlight technical advancements but also as an opportunity for deeper industry collaboration and global business development.

During the exhibition, Cubic introduced its full portfolio of sensor solutions tailored for six strategic sectors:

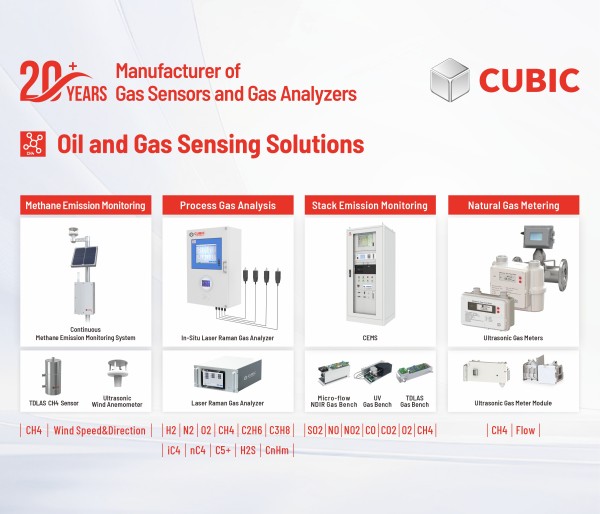

1.Oil & Gas Sensing Solutions

In response to the increasing need for methane detection and emission monitoring in the oil and gas industry, Cubic has leveraged a range of advanced technologies, including ultrasonic technology, tunable diode laser absorption spectroscopy (TDLAS) technology, Laser Raman technology , Non-dispersive infrared (NDIR) technology and ultraviolet (UV) technology, and has successfully developed a complete set of gas sensing solutions, encompassing gas sensors, and gas flow meters, high-end gas analyzers, all of which feature impressive accuracy and high reliability, well-suited for gas emission monitoring through upstream to downstream process in the oil and gas sector.

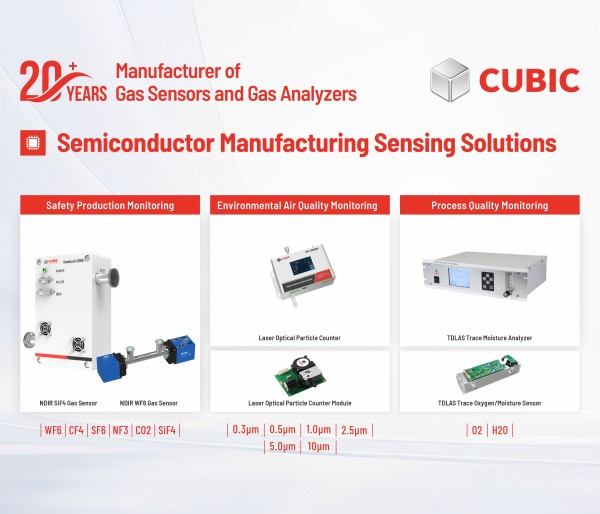

2.Semiconductor Manufacturing Process Sensing Solutions

In semiconductor manufacturing industry, it is essential to minimize yield losses. Cubic has provided reliable optical particle counters based on Light Scattering technology, realize accurate detection of particles of various sizes in a unit volume of air to maintain low levels of airborne particles in cleanroom. For manufacturing quality monitoring, Cubic also designed TDLAS technology-based trace moisture sensor and oxygen sensor, to measure the trace content in ultra-high purity gases with high selectivity, high accuracy and excellent reliability. Furthermore, Cubic specially developed NDIR WF6 sensor and SiF4 sensor to maintain the safety of semiconductor manufacturing process.

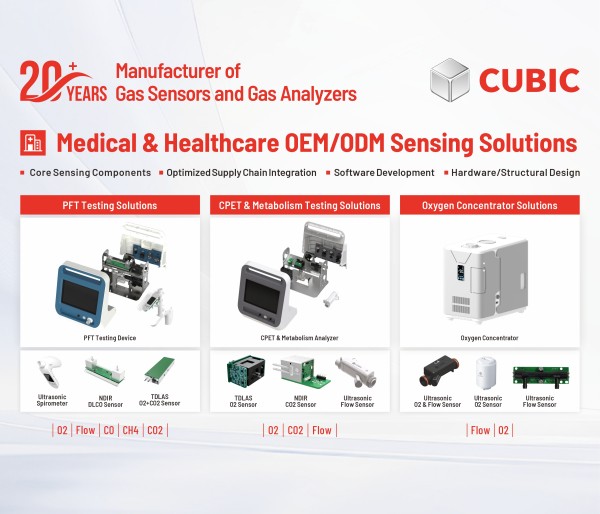

3.Medical & Healthcare OEM/ODM Sensing Solutions

As an experienced OEM/ODM manufacturer, Cubic has leveraged its mature technologies, including ultrasonic, NDIR, and TDLAS technologies to deliver advanced gas sensing solutions for Pulmonary Function Testing, Cardiopulmonary Exercise Testing and Metabolism Assessment, Oxygen Therapy, and Ventilator & Anesthesia Monitoring systems, measuring key parameters of O2, CO2, CO, CH4, and flow level with its core sensing components.

Cubic also offers end-to-end capabilities throughout the entire product development cycle – from sensor solutions and hardware design to software development, mold development, prototype testing, and medical device manufacturing. Beyond customization, Cubic excels in mass production under strict quality control system, efficiently fulfilling diverse and large-scale requirements in the healthcare and medical sectors.

4.Automotive Sensing Solutions

Cubic automotive sensing solutions encompassed a wide range of gas sensor products, including laser scattering PM2.5/PM10 sensors, NDIR CO2 sensors, MEMS MOX AQM sensors, MEMS TC Hydrogen sensors, NDIR refrigerant gas sensors and multi-technologies-integrated Li-battery thermal runaway gas sensors. Additionally, Cubic also designed HTCC, LTCC, NDIR and UVDOS exhaust monitoring gas sensors for environmental monitoring.

With the comprehensive range of gas sensors and gas analyzers, Cubic is dedicated to supporting the automotive industry to face regulatory transition, to meet the requirement of Euro6 and upcoming Euro 7 standards. With an automotive-grade quality management system and extensive OEM experience, Cubic exhaust gas sensing and analyzing solutions can be widely adopted by gas analyzer manufacturers, automotive inspection & maintenance stations, automotive workshops, engine & vehicle manufacturers, relevant scientific research departments and testing institutions worldwide.

5.HVAC & Refrigeration Sensing Solutions

From advanced indoor air quality monitoring to intelligent demand control ventilation, Cubic state-of-the-art HVAC sensing solutions are committed to helping maintain indoor air quality and achieve building energy efficiency. Leveraged mature sensing technologies, Cubic advanced sensors provide high-precision detection of key indoor air quality (IAQ) parameters, including CO₂, particulate matter (PM1.0, PM2.5, PM10), tVOC, humidity, and temperature. Moreover, integrated with self-developed IAQ sensors, Cubic HVAC controllers and monitors will detect fluctuations in environmental conditions and transmit real-time data to indoor ventilation control system, which will adjust ventilation volume accordingly.

With the transition to low-GWP refrigerants, reliable leak detection is more important than ever. Cubic offers a complete set of refrigerant monitoring solutions, from refrigerant gas sensors with IEC 60335-2-40 &UL 60335-2-40 certified, refrigerant gas detectors, to refrigerant gas analyzers, capable of detecting various A2L &A3refrigerants gases including R-32, R-454A, R-454B, R-454C, R-290, R-1234yf, and R-1234ze.

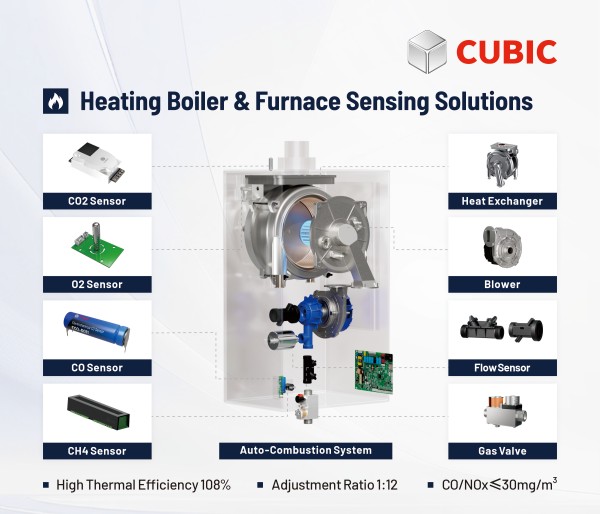

6.Heating Boiler & Furnace Sensing Solutions

Safety and efficiency are at the core of heating applications. Through advanced gas sensing technology and intelligent auto-combustion control systems, Cubic Heating Furnace and Boiler Solutions not only optimize combustion efficiency but also significantly reduce flue gas emissions. By precisely monitoring oxygen (O₂), carbon monoxide (CO), and methane (CH₄) concentrations in real-time, it ensures the air-to-fuel ratio is continually adjusted for optimal combustion, which not only improves thermal efficiency but also minimizes energy waste. In addition, Cubic smart gas sensors enable early detection of flue gas leakage and incomplete combustion, helping to prevent safety hazards including carbon monoxide poisoning and equipment corrosion.

During the exhibition, Cubic welcomed a steady stream of visitors from around the world, connecting with professionals, partners, and potential customers from all around the world, exchanging ideas, and exploring future collaboration opportunities.

While the exhibition has come to an end, Cubic has demonstrated not just the latest sensing solution but also Cubic's passion and long-term commitment to the sensing technologies and innovations through the exhibition. In the future, Cubic will continue to innovate, improve, and work alongside partners around the globe to deliver smarter, more reliable, and more sustainable solutions for various industries including oil & gas, semiconductor manufacturing, medical & healthcare, automotive electronics, HVAC & refrigeration, and heating boiler & furnace.

Cubic sincerely appreciated all customers, partners and industry professionals at SENSOR+TEST 2025, and look forward to next event in 2026!

For more information or to explore business opportunities, feel free to visit us at https://en.gassensor.com.cn/ or contact us via sales@gassensor.com.cn.