EMAIL

EMAIL

Importance of pulmonary function tests

Chronic respiratory diseases are a series of diseases represented by chronic obstructive pulmonary disease (hereinafter referred to as COPD) and asthma. It is one of the four major chronic diseases that seriously affect the health of Chinese residents.

The lung prevalence rate for chronically obstructive people over 40 years old reached 13.6%. The total number of patients was over 100 million, and the number of asthma patients exceeded 30 million, which seriously affected the health and quality of life of the people.

Therefore, pulmonary function tests (PFTS) are an important tool in the investigation and monitoring of patients with respiratory pathology. They can provide important information relating to the large and small airways, the pulmonary parenchyma and the size and integrity of the pulmonary capillary bed. They aid diagnosis, help monitor response to treatment and can guide decisions regarding further treatment and intervention. It is key to the prevention and examination of chronic respiratory diseases. In 2019, the Chinese government's "Healthy China Action (2019-2030)" clearly stated that the awareness rate of COPD among residents 40 and older will reach 15% or more in 2022 and reach 30% or more in 2030.

Incorporate pulmonary function tests into routine physical examinations for people aged over 40 and provide screenings and interventions, diagnosis, treatment, follow-up management, functional rehabilitation and other full-process prevention and management services for high-risk groups and patients. To strengthen the standardized management and to improve early diagnosis and early treatment of COPD at the grassroots level.

World-renowned medical experts, Academician Zhong Nanshan and Academician Wang Chen have been advocating and calling for “Daily pulmonary function tests as blood pressure measurement”. Chronic obstructive pulmonary disease is a preventable and curable disease. To deal with chronic obstructive pulmonary disease, we should focus on prevention so early detection, early diagnosis and early treatment is important.

What are pulmonary function tests?

Pulmonary function tests (PFTs) has been used in clinical practice in China since the 1930s. It is a test method to evaluate the lung ventilation function by measuring the air flow out of the lungs when the patient’s maximum ability to exhale. Simple and most effective means of functional diagnosis and screening.

Spirometer is a device used to help diagnose a lung condition. And there are mainly two types of spirometer in the market: the first type is handheld and portable spirometer, which is used to measure Tidal volume (VT), Forced vital capacity (FVC), Maximal voluntary ventilation (MVV) and other parameters. It is designed for physical examinations of major hospitals and primary medical stations to check for lung diseases; the other type is a lung function testing system, also called a lung function meter workstation. There are many testing items, generally including lung ventilation function (diffusion) and lung volume inspection, and even ECG and blood oxygen test. They are usually used in some large hospitals or physical examination centers.

The handheld and portable spirometer is a simpler, cheaper, safer and reliable, non-invasive lung test method and it is the most suitable product for early COPD screening in the majority of primary hospitals in China.

How to choose the suitable spirometer? Ultrasonic type is the best choice.

In recent years, with the rapid development of modern electronic technology and bioengineering, spirometers are updating continually, and they are more sophisticated and perfected gradually. Traditionally water seal spirometer, wedge Spirometer, dry rolling-seal spirometer are phrased out of market because they could not connect with electronic computers.

After 2000, ultrasonic spirometers have been used internationally to replace traditional differential pressure spirometer, turbine spirometer and thermal spirometer. The main reason is that these three principles have some limitations as below:

1. Hygiene problem: it is difficult to clean thoroughly, and there is a very high risk of cross-infection in long-term use;

2. Unable to measure lower flow;

3. Heavy reliance on gas composition and temperature;

4. Calibration and adjustment required

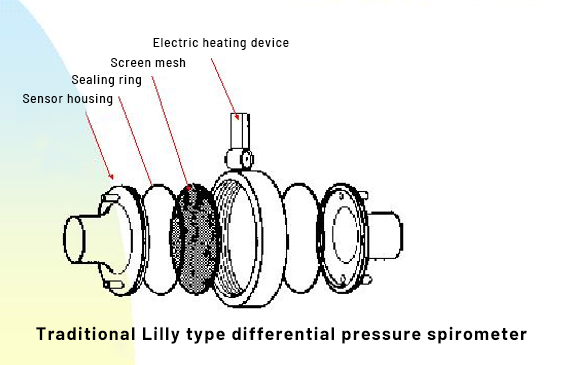

Disadvantage of differential pressure spirometer

The differential pressure spirometer uses the Bernoulli principle to measure the fluid flow in the pipeline. When fluid flows through a pipe there will be a pressure drop that occurs as a result of resistance to flow. When the flow increases, there will be more pressure drops. Measuring the pressure data between the start and end of the pipe and transfer the data to transmitter, then the transmitter could help to determine the fluid flow rate.

Bernoulli's principle shows that the pressure drop is proportional to the square of the flow rate. Using this relationship, 10% of the full-scale flow rate produces only 1% of the full-scale differential pressure. At 10% of the full scale flow condition, the accuracy of the differential pressure flowmeter depends on the accuracy of the transmitter in the range of 100:1 differential pressure. The accuracy of a differential pressure transmitter is usually reduced at low differential pressures within its range, so the accuracy of the spirometer will similarly decrease. Therefore, this non-linear relationship may adversely affect the accuracy and turndown ratio of the differential pressure spirometer.

The advantage of this technology is low cost, but the disadvantage is that the differential pressure signal is nonlinear and will be reduced due to blockage.

1. High respiratory resistance

2. Risk of cross infection

3. The system has large dead space and is easy to block

4. The differential pressure signal is nonlinear, and the measurement range is narrow

5. Affected by water vapor

6. The calibration is cumbersome

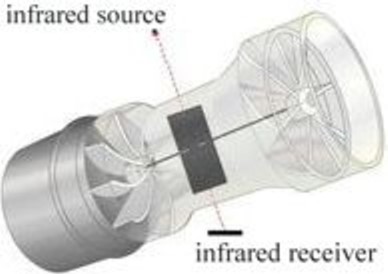

Disadvantage of turbine spirometer

The spirometer based on the turbine principle includes an infrared detector, which detects the interruption of the infrared light source through the rotating blades of the turbine, which is propelled by the passing air. When the flow rate is larger, the turbine spins faster. The infrared detector detects the frequency at which the light from the infrared source is blocked when the turbine passes, thereby obtaining the flow rate. The construction and use of this mechanism is relatively simple, but since it is basically based on a mechanical part in operation, regular recalibration of the device is essential. Therefore, spirometer based on turbines need to be calibrated frequently to ensure that their accuracy is maintained. In addition, because of inertia, the rotary vane cannot start and stop in time, which will also cause large detection errors.

Therefore, the accuracy of turbine spirometer at low flow rates is not high. The ability to respond to rapid changes in flow is insufficient, and the frequent calibration and maintenance during use are all factors that affect the true popularity of this principle.

1. The accuracy of turbine spirometer at low flow rates is not high;

2. The ability to respond to rapid changes in flow is insufficient;

3. The frequent calibration and maintenance during use is necessary.

Advantages of ultrasonic spirometer

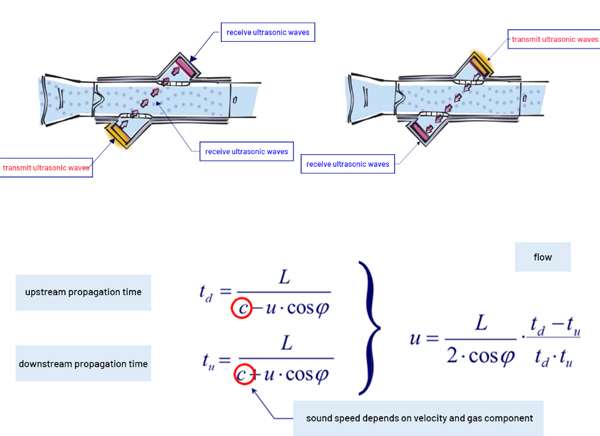

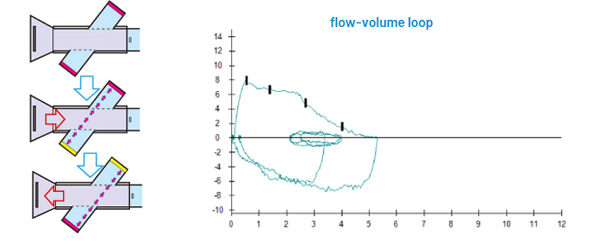

The ultrasonic time difference method uses a pair of ultrasonic transducers to alternately (or simultaneously) transmit and receive ultrasonic waves. By observing the difference in the propagation time between the upstream and the backward flow of the ultrasonic in the medium (gas or liquid), the fluid velocity is measured indirectly, and then calculate the flow data based on fluid velocity.

The flow measurement based on the ultrasonic principle is only influenced by the flow and geometry, and accuracy will not be affected by temperature, gas composition, humidity or pressure. So it is a perfect alternative to differential pressure and turbine principles, and is the best choice for spirometer.

Advantages for ultrasonic spirometer:

1.No drift, no preheating, no calibration, no maintenance (flow measurement only depends on time measurement and sensor geometry, so no calibration)

2.Non-contact flow detection technology, the ultrasound probe does not touch the patient, preventing cross infection

3.High measurement accuracy, especially for very weak airflow

4.Direct flow measurement, wide linear range, no nonlinear distortion

5.There are no obstacles in the middle of the breathing tube, no breathing resistance

6.Not afraid of water vapor, real-time BTPS correction

7.The sensor is not affected by humidity, air pressure and pollution

8.Can obtain gas concentration information at the same time

9.Greatly expanded the scope of application: adults-children-newborns

Cubic ultrasonic spirometer

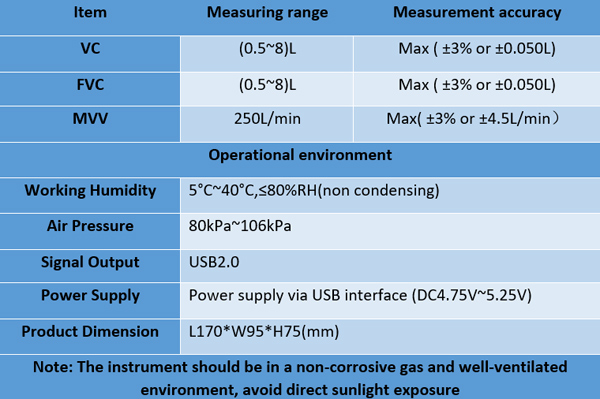

Cubic handheld ultrasonic spirometer Gasboard-7020 (Registration Certificate No.: 20122211718), adopts ultrasonic time difference flow technology, is a high-tech product for pulmonary ventilation function and spirometry test, and is used to check asthma, COPD, other respiratory disease. It works as a powerful measuring instrument for assessing the lung function of smokers, chronic cough and sputum.

1、Support many items report, including

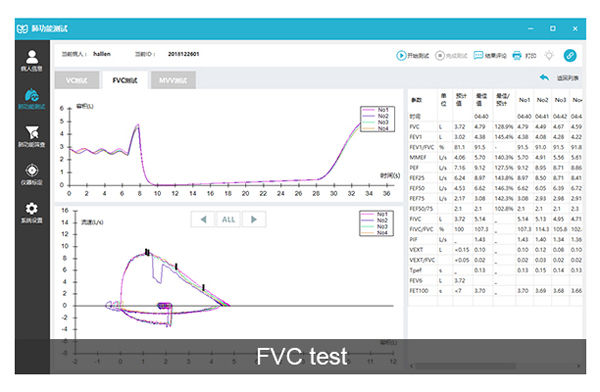

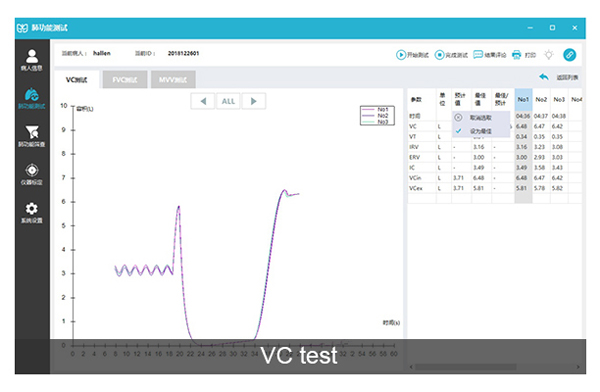

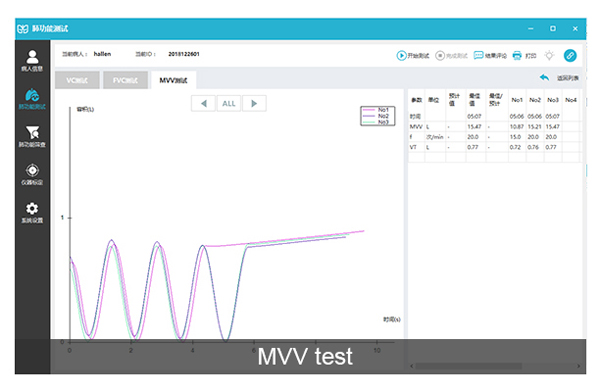

Forced vital capacity (FVC): FVC, FEV1, FEV3, FEV6, FEV1/FVC, FEV1/VC Max, PEF, FEF25, FEF50, FEF75, MMEF, VEXP, FET and so on; Peak Inspiratory Flow( PIF); Vital capacity (VC): VC,VT,IRV,ERV,IC and so on;Maximal voluntary ventilation (MVV)

Precise double-way detection. There is no obstacles sensor internal. So it could test the lung function parameters of exhalation and inhalation and present the flow-volume loop of the complete breathing cycle, meeting the needs of clinical application and early screening.

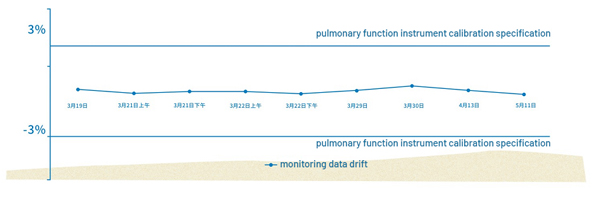

Stable without drifting, suitable for long-term use. Gasboard-7020 monitoring data drift for 2 consecutive months is significantly lower than the national standard (JJF 1213-2008: pulmonary function instrument calibration specification).

Exhalation and inhalation indicators can be detected, and dynamic curves can be displayed in real time.

2. Product quality control function

Compliance to quality standards, the instrument supports volume calibration and three flow rate linear verification;

With automatic measurement of environmental parameters (temperature, humidity, atmospheric pressure) and BTPS correction function;

Equipped with necessary inspection calibration and calibration equipment for pulmonary function tester, 3 liter calibration cylinder, in future also can provide necessary quality control calibration testing services according to clinical needs;

The system software can perform automatic quality control rating based on the test results.

3.Software

Test module: lung ventilation function test (FVC, VC), bronchial diastolic test, etc.; real-time display of flow volume (F-V) curve, time volume (V-T) curve, etc.;

Quality control management module: capacity calibration, linearity verification, and formation of quality control reports; automatic calculation of quality control ratings; according to ATS/ERS intelligent recommendation of highly acceptable measurement curves;

Quality control management module: capacity calibration, linearity verification, and formation of quality control reports; automatic calculation of quality control ratings; according to ATS/ERS intelligent recommendation of highly acceptable measurement curves;

Customer information management module: It can input basic information, symptoms, risk factors, respiratory disease history, physical measurement results, contraindications, and regular follow-up management of patients at high risk of COPD and patients;

Follow-up questionnaire modules: CAT, mMRC, COPD-SQ and other questionnaire configurations;

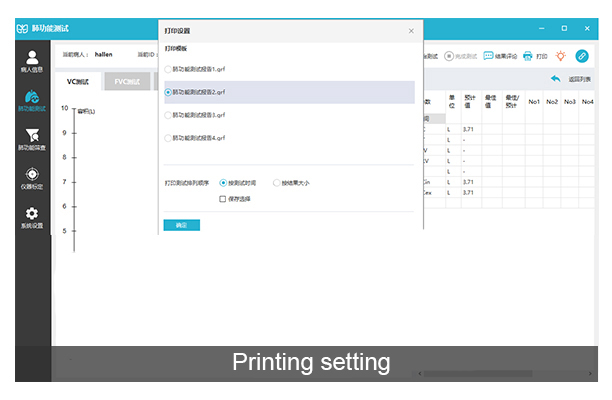

>Report management module: supports a variety of report templates, including spirometer examination and bronchodilation test;

Work ledger module: test result statistics and report export;

Data communication module: support docking with hospital HIS system; support multi-center and hierarchical diagnosis and treatment work mode and other functions;

Account management module: account and password management, basic account information configuration, version upgrade, device management, estimated value selection, data synchronization, etc.

4、Cloud data management function

Project management functions: including basic information, summary information, follow-up content settings, project participating units, etc.;

Quality control management function: equipment quality control calibration report, inspection report quality management; check the quality control report of a certain center, you can comment and leave a message online;

Customer information management: including the name, gender, date of birth, nationality, ID number, marital status, occupation, household address, actual residential address, contact phone number, outpatient number/hospital number, symptoms, Risk factors, respiratory history, physical measurements, contraindications, follow-up management of patients at high risk of COPD, etc.;

Pulmonary function report management module: lung function report summary; lung function quality control level; online view of lung function report details; online interpretation of comments; FVC inspection quality, FEV1 inspection quality, lung ventilation dysfunction type, lung ventilation dysfunction degree, diastolic Display of analysis charts such as test negative/positive, GOLD classification, etc.; real-time view and dynamic display of lung function tests in our center, region, and province;

Data export function: support custom time range data export; support all data export, including basic information of inspection objects, lung function report data, follow-up data, etc.;

Data sharing: The basic information of the inspection object and related data and information such as lung function examination and diagnosis can be transmitted and shared to residents' electronic health files and regional population health information platforms;

Security requirements: protect the privacy of the investigators and ensure the security of the information platform and the collected information;

With customizable extension functions.

Cubic introduction

Cubic is located in "Wuhan-China Optics Valley", covering an area of 20,000+ square meters. Cubic is a high-tech enterprise specializing in R&D, production and sales of gas sensors and gas analysis instruments.

Since its establishment in 2003, Cubic has always focused on technology innovation. In addition to ultrasonic (Ultrasonic), Cubic also mastered non-dispersive infrared (NDIR) technology, light scattering detection (LSD) technology, ultraviolet differential absorption spectroscopy (UV-DOAS) technology, thermal conductivity (TCD) technology, laser Raman (LRD) technology and other core gas sensing technologies, forming two major industrial ecology of gas sensors and gas analysis instruments. The products are widely used in domestic and international air quality monitoring (indoor, outdoor, Automobile), health care, energy measurement, industrial process energy saving and emission reduction monitoring and other fields. In addition to pulmonary function meters, the Cubic gas sensors based on ultrasonic and infrared principles are widely applied in oxygen generators, ventilators, and patient monitoring.

Cubic has cooperated with domestic authoritative organizations to develop ultrasonic pulmonary function testing instruments and carry out clinical trials, successfully establish a joint laboratory for cooperative research and development of lung function quality control technology. With the implementation of the "Healthy China" action policy, based on advanced gas core sensor detection technology and loT big data application technology, Cubic will continue to launch more medical device in the future.