EMAIL

EMAIL

China’s energy consumption experienced rapid growth over the few decades. Forecasts for total energy demand for 2020 in China is 5 billion tons of standard coal. Traditional coal energy could not satisfy our energy demand. A shift to “clean” alternatives, such as natural gas is on the way. China has focused on natural gas to replace coal since 2014, eliminating outdated coal-fired power generation units which have great damage to our environment.

Natural gas is a new and clean energy and gas demand is highly robust since the beginning of the Covid-19 outbreak, shielded to some extent by extended heating season and domestic price cuts that helps the gas remains competitive against traditional energy source. Natural gas consumption is rising year by year. Accordingly gas meter industry is enjoying the prosperity for development. Due to its mature technology, stable quality and low price, diaphragm gas meters have been widely used. With the development of computer and microelectronics technology, Intelligentization has been utilized in diaphragm gas meters. So diaphragm is still a mainstream in gas meter industry.

However, the diaphragm gas meter has a complex structure. It is easy to wear, and it is also easily affected by external factors such as the temperature and pressure of the pipeline medium, resulting in a decrease in measurement accuracy. Thermal (MEMS) gas meter is a new type of gas measuring instrument that uses the principle of heat transfer to measure the flow of gas under standard conditions. It adopts a fully electronic structure, no mechanical operating parts, small size and high accuracy. Although it can be corrected for specific natural gas components, it is still susceptible to a variety of different gas components, and the correction of temperature effects is relatively complicated. At the same time, long-term contaminant deposition slows down the response of MEMS chips and affects accuracy. Ultrasonic gas meters have attracted great attention at home and abroad due to their advantages of non-contact measurement, no moving parts, no pressure loss, extremely high measurement accuracy and can be combined with more intelligent applications. It is a hot product in the field of gas measurement in recent years.

In fact, as early as the 1990s, many gas companies in Britain, Germany and other countries have successively developed ultrasonic gas meters. Limited by factors such as ultrasonic probes, timing chips, and electronic technology at the time, the price of these ultrasonic gas meters was still very high compared with traditional diaphragm gas meters. After entering the 20th century, the price of key components of ultrasonic gas meters has been greatly reduced, ushering in the rapid development of ultrasonic gas meters. Tokyo Gas Company of Japan carried out various field tests of ultrasonic gas meters in July 2003. In 2005, it was the first to install 5,000 ultrasonic gas meters in users' homes. In 2008, ultrasonic gas meters were extensive used. At present, the international ultrasonic gas meter technology mainly comes from companies such as Panasonic and Siemens. They have been deeply involved in the ultrasonic field for many years. They have many patents in flow channel structure, software algorithm, ultrasonic transducer, module and the whole machine. Although many domestic gas meter companies have begun to develop ultrasonic gas meters, most manufacturers still use Panasonic’s ultrasonic gas meter sensor solutions, that is, purchase Panasonic’s circuit boards and ultrasonic detectors, and assemble the ultrasonic gas meters with their own matching shells. This model makes the price of domestic ultrasonic gas meters high, and market promotion is restricted. Gas meter industry ecology in China has basically been established. Therefore, actively carrying out independent intellectual property rights and technical research on ultrasonic gas flow sensors that can meet the requirements of gas meter specifications, is of great significance for breaking the foreign technology monopoly and promoting the transformation and upgrading of China's gas meters.

(1) Independent research and development of ultrasonic transducer.

At present, the core components of ultrasonic transducers that meet the measurement requirements of ultrasonic gas meters are basically imported, and the price accounts for 40% of the total cost. The core difficulty of domestic ultrasonic gas meters lies in the independent research and development of ultrasonic transducers. The independent research and development of ultrasonic transducers is mainly limited by its bandwidth and high and low temperature characteristics. Generally, there are two ultrasonic transducers on the inner pipe of the ultrasonic gas meter. The distance between them is 50-70 mm. The bandwidth of the transducer is required to reach more than ±10%, and the measured height of the second emission wave should be as high as possible, so that it can reach more than 100mV. In addition, the test drift at different temperatures needs to be considered.

(2) The performance and stability of the gas meter.

Because there are no mechanical parts, ultrasonic gas meters are theoretically more stable than traditional diaphragm meters. However, diaphragm meters have been widely accepted by customers for many years. How to prove that the stability of ultrasonic gas meter could meet the requirement of gas meter company and how to make market accept this type ultrasonic gas meter are very important.

(3) The problem of gas pollution.

Like the diaphragm gas meter, long time operation of the ultrasonic gas meter, dust or impurities in the gas will adhere to the ultrasonic transducer, which affects the sensitivity of the transducer, thereby affecting the measurement accuracy of the gas meter.

(4) The adaptability of gas source.

The density of natural gas is smaller than that of air, and the signal is also weaker than that of air; after gas with different density passes through the ultrasonic transducer, the signal waveform will be very unstable. Ultrasonic signal transmission will be affected by various factors such as the gas medium, environment (temperature, humidity, pressure) and reflection in the pipeline. The received ultrasonic signal usually has waveform changes and amplitude changes. Therefore, if the household wave gas meter wants to be widely used for residence, the adaptability to the gas source is the most important hurdle that needs to be overcome.

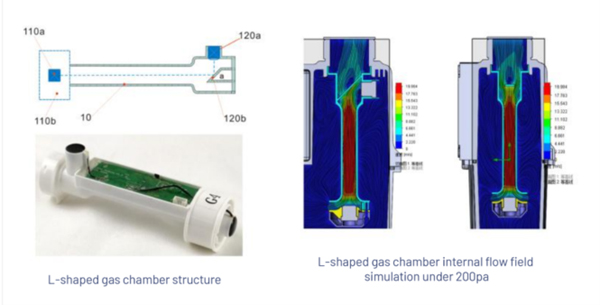

Since its research on ultrasonic gas sensors in 2008, Cubic has made breakthroughs in the fields of ultrasonic transducers, time measurement chips, automatic time difference calculation methods, and simultaneous sensing of process components, especially realizing mass production and application in fields including ultrasonic oxygen flow sensors and ultrasonic biogas meters and have a good technical and industrial foundation. In response to the special requirements of ultra-wide range ratio, wide temperature range, anti-contamination ability, and pulsating airflow measurement required by domestic gas meters, Cubic has developed a new type of residential ultrasonic gas meter with gas density measurement function. At the same time, Cubic designed an L-shaped ultrasonic gas chamber channel through computational fluid dynamics simulation to further reduce costs and improve anti-fouling performance, thereby enhancing the competitiveness of ultrasonic gas meters.

Figure 1: Ultrasonic gas meter module and internalflow field simulation of L-shaped gas chamber

Industrial diaphragm gas meters and Roots gas meters are adopted for commercial and industrial gas measurement. In order to ensure accurate measurement, the ultrasonic gas flow meter uses multiple sets of ultrasonic detectors, which have high cost and power consumption. Based on the research experience of domestic gas meter module, Cubic optimized the design of the fairing at the air inlet through fluid mechanics simulation to ensure that the gas entering each sub-chamber is more uniform and stable. As a result, only a set of ultrasonic detectors can be used to complete the measurement of commercial and industrial gas meters, ensuring accuracy and low cost.

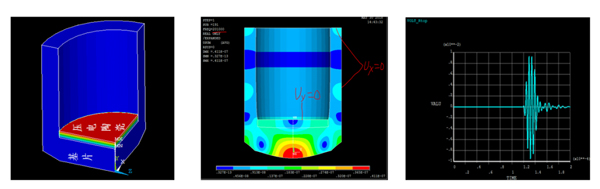

In order to further improve the performance of the ultrasonic gas meter module and reduce the cost, Cubic determined the optimal detector material and structure size through finite element simulation analysis of the diameter and thickness of different piezoelectric ceramics and different substrate, and so on. The corresponding process plan is developed to realize the independent production of high-sensitivity ultrasonic detectors. At present, the ultrasonic detectors for Cubic gas meters have been trial-produced and applied in small batches.

Figure 2: Design simulation of ultrasonic detector for gas meter

In addition, Cubichas also implemented innovations in the core algorithm, adopting dual-thresholdzero-crossing detection and data selection technology, and automatic zeroingalgorithm to accurately calculate the gas flow rate and offset the impact ofthe zero point drift on the flow rate measurement.

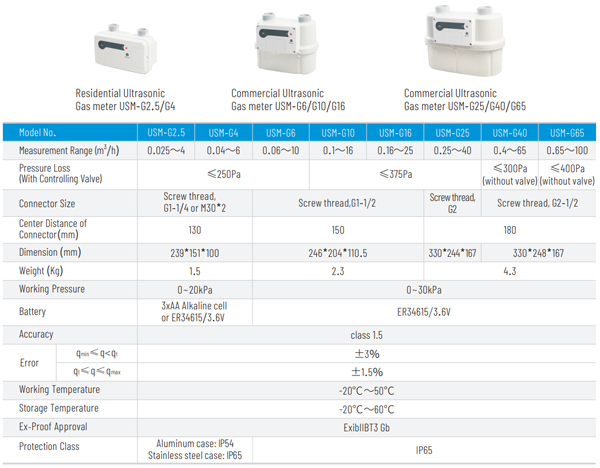

Based on the patented core technology of gas flow sensor hardware and software, Cubic has successfully developed residential and commercial gas meters to meet the needs of residential, commercial and industrial customers. The core sensor components are shown in Figure 3:

Figure 3 coresensor components for ultrasonic residential and commercial gas meters

After the core gas meter gas flow sensor developed, the gas meter can beassembled by utilizing the casing, membranevalve, power management, etc. that it had in the past. Figure 4 is a G4 gasmeter using an ultrasonic core flow sensor.

Figure 4. G4 ultrasonic gas meter (built-inlocalized core flow sensor)

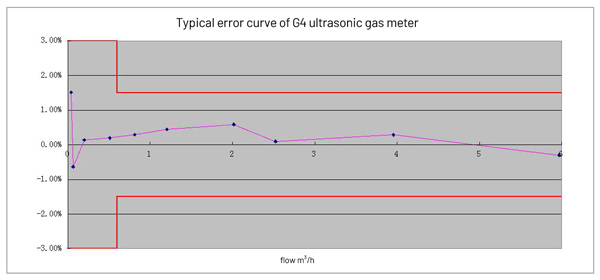

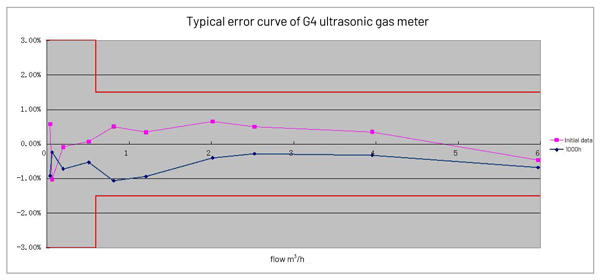

According to the measurement requirements of the gas meter, a wide-range gas meter error characteristic and durability experiment were carried out.

Figure 5. Typical error curve of G4 ultrasonic gas meter

Figure 6. Durability error curve of G4 ultrasonic gas meter

Cubic not only checked the EN-14236 European "ultrasonic-domestic-gas-meters" standard for complete testing. In addition to the basic tests shown above, Cubic also performed linearity, pressure loss, high and low temperature, and alternate hot and humid, dust resistance, pulsating flow and other tests. Tests show that Cubic gas meters based on the core module of the ultrasonic gas flow sensor meet the requirements of various indicators of the gas meter.

Cubic Sensor and Instrument Co.,Ltd was established in 2003 in"Wuhan-Optics Valley of China", covering an area of 20,000+square meters. It is a high-tech enterprise specializing in the development,production and sales of gas sensors and gas analyzers.The company has developed gas transmission based on the principles ofnon-dispersive infrared (NDIR), light scattering detection (LSD), ultrasonic(Ultrasonic), ultraviolet differential absorption spectroscopy (UV-DOAS),thermal conductivity (TCD), laser Raman (LRD), etc. The sensor technologyplatform has formed two major types of industrial ecology, gas sensors and gas analyzers, and dozens of different products, which arewidely used in home appliances, automobiles, medical treatment, environmentalprotection, industry, energy measurement and other fields at home and abroad.

Cubic is one of the first typical intellectual propertydemonstration enterprises in Hubei Province. Cubic has built the Hubei ProvinceGas Analysis Instrumentation Engineering Technology Research Center and theHubei Province Enterprise Technology Center. Cubic has undertaken the nationalmajor scientific instrument and equipment development special projects, Internet of Things development projects for the Ministry ofIndustry and Information and other national technologies. Total of 97patents were obtained for development projects, including 29 domestic andforeign invention patents. Cubic and its subsidiary Hubei Cubic-RuiyiInstrument Co., Ltd. were selected as a demonstration enterprise of the“one-stop” application plan for industrial strong base sensors of the Ministryof Industry and Information Technology in 2019. With long-term technologicalaccumulation, good product performance and international vision, Cubic hasobtained the recognition of many well-known domestic and foreign partners, andthe products are exported to more than 80 countries and regions.