EMAIL

EMAIL

With the rise of the tertiary industry, the catering service industry has developed rapidly, bringing convenience to people's lives, but the direct emission of oil fume also causes pollution to the atmospheric environment. The composition of oil fume gas is complex, and the particulate matter and volatile gaseous organic matter in oil fume gas are one of the important reasons for the formation of haze. In order to effectively promote the treatment of atmospheric environment, oil fume treatment is imperative.

Cooking fume emissions have large numbers of widely distributed feature. The traditional cooking fume emission supervision is mostly for regular on-site inspections by relevant government departments. However, this method has the problems of high cost and low efficiency, and it could not completely and efficiently solve the problem of oil fume pollution. In recent years, with the promotion of various environmental policies, many areas have begun to introduce cooking oil fume online monitoring systems, which can remotely and real-time monitor whether the oil fume emission in the area could meet the national standard GB18483-2001 "Fume Emission Standard for Catering Industry" or not. So accurate control for oil fume pollution could be achieved. At the same time, it also saves a lot of manual inspection costs.

To achieve accurate measurement of the cooking fume online monitoring system, the core is the cooking oil fume sensor. The working environment of oil fume monitoring equipment is special. Hydrocarbon gas in cooking oil fume could be easily absorbed and water vapor was also easily condensed. The constantly changing air flow will also bring huge challenges to the accurate detection of the cooking oil fume sensor.

1. The pollution of oil fume to the detection sensor. During the long-term operation of the sensor, the oily dirt in the oil fume will inevitably cause certain pollution to its internal components, especially the photosensitive detection area, which will easily cause deviations in the measured value and affect the monitoring effect.

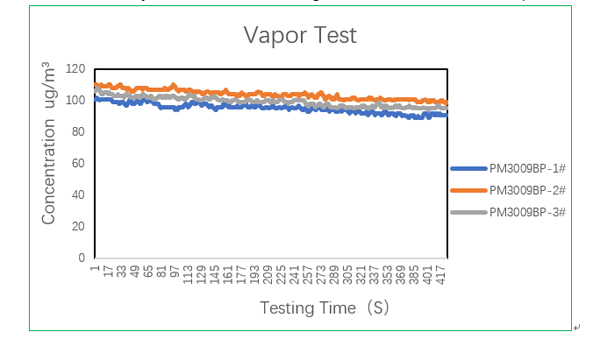

2. The interference of water vapor on the measured value. The water vapor in the oil fume gas will condense to form suspended droplets. The sensor based on the laser scattering principle will misjudge it as a particulate matter, which will also cause a large deviation in the measured value and affect the monitoring effect.

3. The influence of airflow changes in the flue on data stability. The airflow in the flue will change the fan speed, and its flow rate changes in a large range, which can easily affect the sampling flow rate of the sensor, causing a large deviation in the detection value and affecting the monitoring effect.

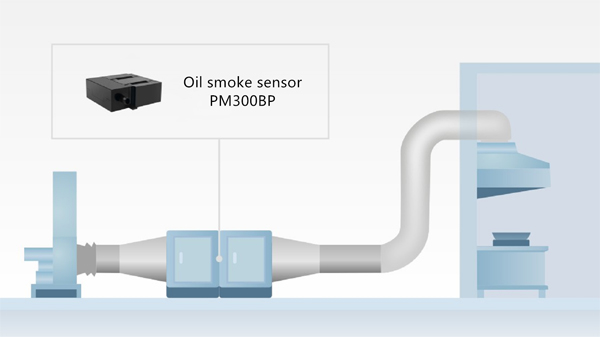

Based on many years of research on the application for light scattering technology and particulate matter sensors, Cubic developed the oil smoke sensor PM300BP and the oil smoke online detector OPM-6309 for the unique application environment and customer demand in the field of oil fume emission monitoring, which successfully solved the problem. It is subject to oil fume pollution, and measurement accuracy is vulnerable to variations in sampling airflow, and water vapor can easily cause misjudgment of sensor measurement values.

Figure 1: Oil smoke sensor PM300BP and the oil smoke online detector OPM-6309

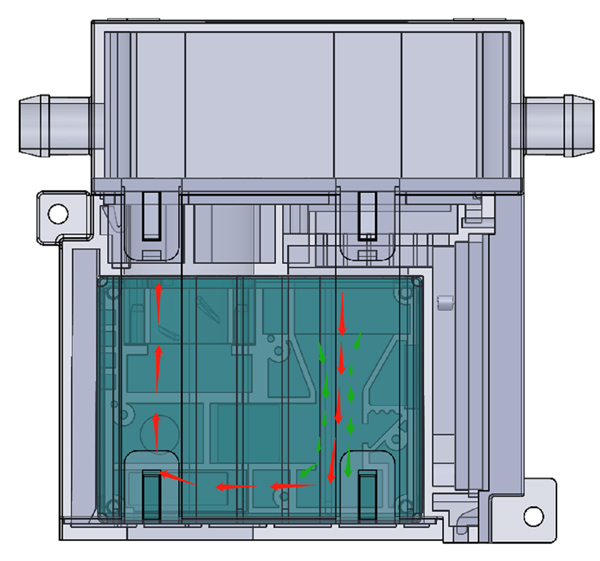

1. The self-cleaning innovative structure design solves the pollution caused by oil fume to the sensor. Cubic adopts an innovative structural design, which makes the organic matter in the lampblack gas difficult to be absorbed in the light scattering area of the sensor, avoiding the influence of lampblack adsorption.

Figure 2: Cubicinnovative self-cleaning structure

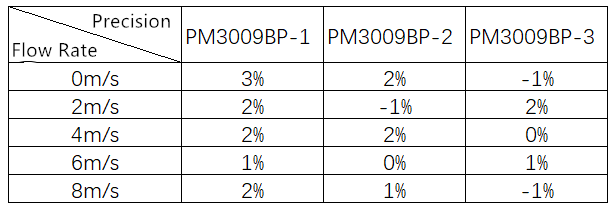

3. The data is stable without being affected by the change of air flow velocity in the flue. Cubic PM3009BP adopts a unique sampling flow channel design, so that its sampling flow is not affected by the change of gas flow velocity in the air channel.

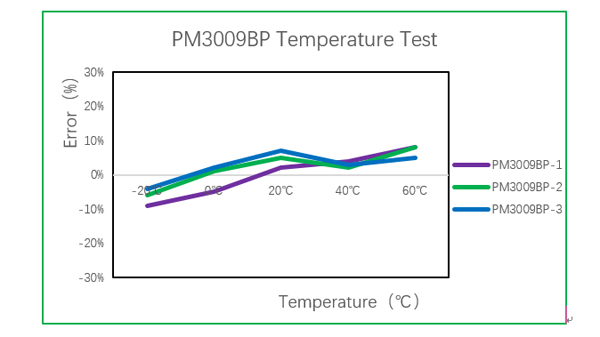

4. Better temperature resistance. Due to the high temperature of oil fume gas, Cubic PM3009BP selects high-temperature-resistant lasers, sampling fans and other components to better meet the detection requirements of high-heat gas in the flue.

Cubic Sensor and Instrument Co., Ltd is a high-tech enterprise specializing in R&D, production and sales of gas sensors and gas analysis instruments. Based on non-dispersive infrared (NDIR) technology, light scattering detection (LSD) technology, ultrasound (Ultrasonic) technology, ultraviolet differential absorption spectroscopy (UV-DOAS) technology, thermal conductivity (TCD) technology, laser Raman (LRD) technology, Cubic has launched many types of gas sensing platforms , formed two major industrial ecology: gas sensors and gas analysis instruments and developed dozens of different products which are widely used in home appliances, automobiles, medical, environmental protection, industry, energy measurement and other fields at home and abroad.

Cubic Sensor and Instrument Co., Ltd is the first batch of intellectual property demonstration construction enterprises in Hubei Province. It has established the Hubei Province Gas Analysis Instrumentation Engineering Technology Research Center and the Hubei Province Enterprise Technology Center. Cubic has undertaken the national major scientific instrument and equipment development special projects, the Ministry of Industry and Information Technology Internet of Things development special projects and other national technologies development project. In 2019 Cubic and its subsidiary Hubei Ruiyi are determined to be selected as a demonstration enterprise for the “one-stop” sensor industry application plan by the Ministry of Industry and Information Technology. Cubic won the "Most Influential IoT Sensor Enterprise Award" issued by China IoT Industry Application Alliance.

With long-term technology innovation, high product performance and international marketing vision, Cubic has obtained the recognition of many well-known domestic and foreign companies. Cubic gas sensors have obtained successful cooperation with global well-known brands such as Midea, Gree, Haier, Hisense, Xiaomi, Lake Electric, YuWell Medical, Philips, Daikin, Panasonic, FAW-Volkswagen, Valeo, Mahler, and Bosch, etc.

Cubic gas analysis instruments, based on the aforementioned core gas sensing technology, are widely used in various fields such as environmental monitoring, metallurgy, coal chemical industry, and biomass energy, and play an important role in energy saving and emission reduction. Cubic non-dispersive infrared gas sensors and portable infrared biogas analyzers, micro-fluid infrared flue gas analyzers, and infrared syngas analyzers have successively obtained national key new product certificates. Especially the infrared syngas analyzer won the Excellent Product Award of the Chinese Instrument and Meter Society, and its core technology won the Hubei Province Invention Patent Gold Award.