EMAIL

EMAIL

Particles in the air have ascattering effect on incident light, and the intensity of the scattered lightis related to the particle size. Inhaling air particles from the sampling vent,and the air dust particles will pass through the light sensitive area. So the dust particles are irradiated by light and will scatter a light pulse signal whichis proportional to the particle size. This signal is received by the photosensitive device and converted into a corresponding electrical pulsesignal. Amplify, by counting the number of electrical pulses in a detectioncycle, the number of particles in the air sampled per unit (pcs/L) can be detected,which can then be converted into mass concentration (μg/m3) through analgorithm.

(1) Automatic correction technology

In order to reduce costs and enrich application scenarios, in recent years, laser dust sensors have used fans to take place of expensive air pumps to extract outside sample gas from the external environment. However, with temperature and humidity changes, and environmental aging, etc., the fan speed will change, which will have an influence on the detector signal. So the measurement accuracy could not be guaranteed. By research on the relationship between the detector signal, the variable fan speed and the dust particle concentration, Cubic successfully developed an automatic correction technology that is correcting the fan speed change through a software algorithm thereby significantly improving the measurement accuracy.

(2) Automatic Particle Identification (API)

The laser dust sensor directly measures the particle size and quantity of the dust. To output the mass concentration, the density must be determined in advance. When the dust sensor's role scene is extended to outdoor environment monitoring, it becomes little complex. As we know, the outdoor environment is more complex and changeable than the indoor environment. So the distribution of dust particles in different scenes is different and the dust particles density will change accordingly.

In order to accurately identify the scene where the sensor is located indoor or outdoor, and determine the density to reflect the dust concentration, automatic particle identification (API) technology has emerged.

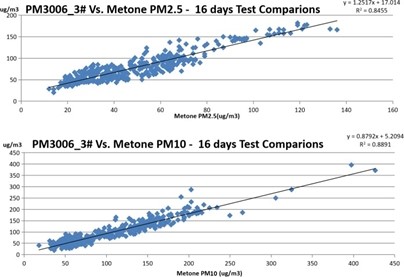

API technology eliminates mutual interference through algorithms, calculates particle density through particle size distribution characteristics, and calculates the dust concentration, so as to achieve reasonable feedback on the dust concentration of different distribution characteristics in different scenarios and multi-channel output of particles of different particle sizes. Cost-effective technical solutions. With Automatic Particle Identification technology, Cubic dust sensor can achieve almost the same measurement results as standard instruments (Belta ray method) under different dust source environments such as PM2.5 and PM10, and has automatic temperature compensation and good durability.

(Long-term comparison of outdoor dust sensor output and Belta ray standard instrument value)

(3) Antifouling technology

Dust and condensed water carried in the measuring gas will affect the performance of the dust sensor. Especially in the automotive scene where the vehicle-mounted laser dust sensor is applicable, condensed water and large particles of dust are extremely common. In order to effectively improve the dust resistance and stability of the dust sensor, Cubic has conducted a lot of research in preventing moisture condensation and dust deposition, forming a dust sensor anti-fouling technology, which is widely used in the Cubic dust sensor products.