EMAIL

EMAIL

The development and application of Cubic Sensors in light scattering technology can be traced back to the 2008 Shanghai World Expo. In order to meet the product development needs of a well-known Chinese domestic heating, ventilation and air conditioning (HVAC) customers, Cubic has successfully developed an integrated air quality module for customers, including various indicators such as PM2.5, CO2, formaldehyde, magnetic radiation, temperature and humidity. Since then, Cubic has continued to deepen the research and innovation of particle sensors. In the beginning, Cubic offered core gas sensing modules for industrial high-end instruments and equipment. Now Cubic could offer integrated gas sensing solutions for various types of indoor smart home appliances, OEM automotive appliances, outdoor dust and grid monitoring equipment, comprehensive factory cleanliness monitoring systems. Cubic has successfully covered multiple application fields, involving a variety of different application scenarios such as indoors, outdoors, and cars, and realized the development and application of the entire product line based on light scattering technology.

Indoor dust detection

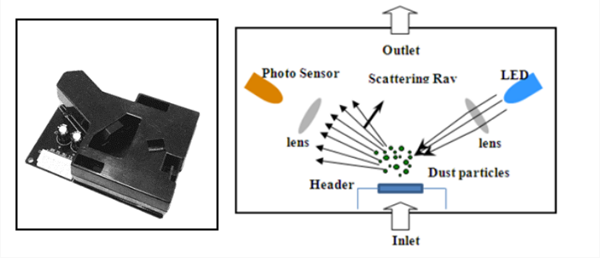

Early air purifier customers mostly used Japanese brand dust sensors for particle detection, which were only used to display different colors (usually red for over-standard, yellow for early warning, and green for good conditions) or 1, 2, 3 digital levels to show the purifying effect of the device. This level display method can only be used as a reference for trend changes, and cannot convey the real situation of the environment. There are two reasons for this. One is that early air pollution such as haze is not too serious, and the market does not require accurate display; the other is that the application of light scattering technology in the field of household appliances is limited to a lower cost. Achieve further technical upgrades. This type of sensor is represented by Japanese and Korean brands, and the product appearance and design ideas are as follows:

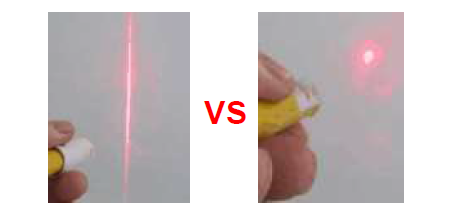

"High technology, low cost, mass production" is the direction that Cubic has always been dedicated to. Cubic immediately established a research and development team to actively respond to the market demands. Through nearly one year hard work, Cubic completed the mass production of the first laser dust sensor PM2005 which is specifically developed for air purifiers, achieving a domestic product breakthrough in this field in China. PM2005 upgrades the LED light source to a laser light source, adapting a fan to achieve stable airflow control, and using a single-chip microcomputer realizes the digitization of the output signal. What’s more, Cubic laser dust sensor PM2005 is equipped with various data communication transmission methods such as UART, IIC, and PWM. It is truly online real-time and precise measurement and has high cost performance. And it is the first choice for purifier manufacturers at home and abroad.

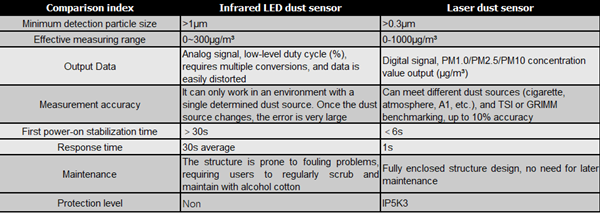

Performance comparison between LED infrared dust sensor and laser dust sensor:

As can be seen from the above table, if the user needs fast and accurate real-time values display, laser dust sensors are undoubtedly a more reasonable choice. And if the requirement is only a level display, or just a simple number display, and no further demand for measurement accuracy, LED infrared dust sensors could be still your suitable choice.

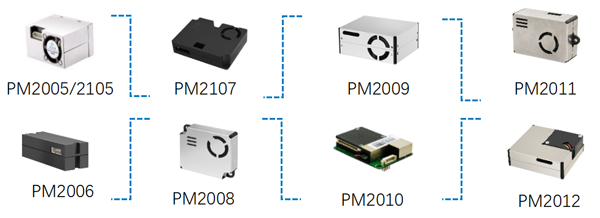

Found in 2015, Cubic has continuously launched new products according to market demands. At present, laser dust sensors have many products such as PM2107, PM2008, PM2009, PM2012, etc. Customers may have many choices according to their various demands for structure and performance.

Dust detection in the car

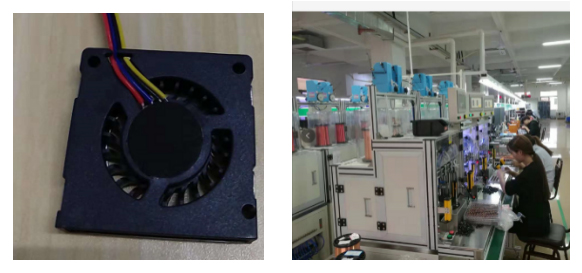

Secondly, whether it is the internal circulation or the external circulation of the car air conditioner, the airflow changes in the cabin are large. This is also very different from the static indoor air. If using the civil dust sensor, the detection data will be affected by the airflow. Large fluctuations due to the impact of changes bring a bad experience to users. According to the actual application situation, Cubic upgraded the bearing fan in the civil dust to a large-size blower, which has a stronger ability to resist wind resistance. It can also connect an external air duct of 10-30cm to ensure the stability of the detection data.

Since there were no blowers on the market that fully met the requirements of vehicle regulations for environmental temperature and reliability, the supplier’s customization cost was expensive and time coordination could not meet the project’s mass production needs. Cubic invested in opening its own vehicle-level fan factory. We developed and designed in full accordance with the performance and reliability requirements of automotive applications. It has been mass-produced and applied to many models, achieving self-made core and key components.

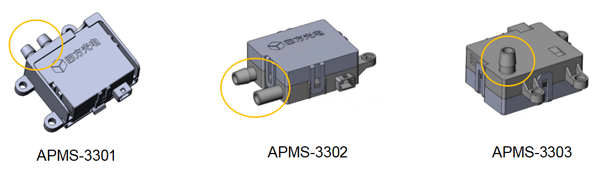

Finally, due to the large number of vehicle models available from OEMs, both newly designed models and mass-produced modified models, the installation and fixing space for the dust sensor is very limited. Cubic aims to reduce the cost of new product development for customers, and shorten the development cycle. Cubic innovatively introduced the creativity of platform-based development, and launched a platform-based series of products APMS-330X. This series of products can support individual design for the air inlet and outlet and connectors position without changing the PCBA and hardware design.

Outdoor Dust Monitoring

Construction site dust and urban grid monitoring are an important part of air pollution prevention and control. The core sensor for detection in the monitoring system is especially important. It must have the three characteristics of scientific reliability of the product, completeness of application and economic applicability. In the field of outdoor dust and grid monitoring in China, the monitors of weighing method and β-ray absorption method were used in the early stage. However it could not realize online real-time monitoring. The investment cost and maintenance cost is high so that it did not get widespread application in the market. Also the residential laser dust sensor in civil air purifiers could not be used in the outdoor temperature environment of -30~70℃. Since the outdoor environment often encounters frost and dew, the water vapor entering the sensor will seriously affect the measured value, and even cause permanent damage to the sensor. Residential laser dust sensors have low laser power and low sampling flow, and PM10 recognition rate is very low. Civil laser sensors usually calculated PM10 concentration based on the number of PM2.5, resulting in distortion of PM10 monitoring data.

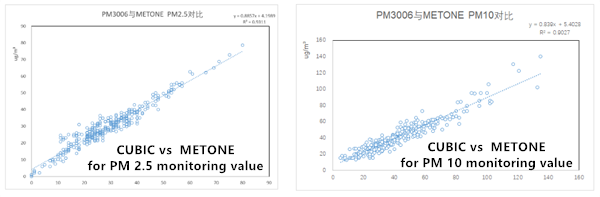

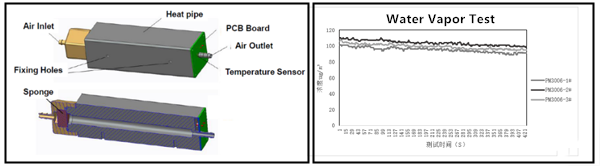

By accurately grasping the pain points of the above-mentioned customer needs, Cubic continues to overcome difficulties, leverages the long-term accumulated technical advantages on the principle of light scattering, and combines the accumulated experience in indoor and car dust detection to develop the dust sensor-PM3003, PM3006 series products have the following key advantages and features:

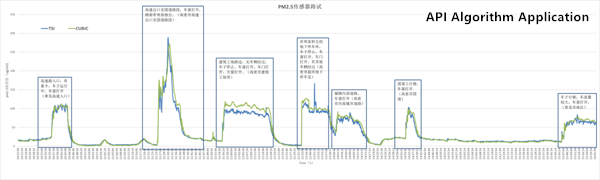

First of all, the use of wide-temperature high-power linear laser light source, API dust automatic identification technology, advanced flow channel design to achieve anti-pollution, high-humidity environment water mist removal device, etc., to create a new low-cost to achieve accurate outdoor dust measurement, the correlation between the real-time monitoring values of PM2.5 and PM10 and β-ray absorption method monitoring equipment can reach 0.9 or more.

Secondly, PM3003X and PM3006 laser dust sensors use constant power, linear light sources with a working temperature of -30~70℃, and their optical power is up to 100mW, which is more than 20 times higher than that of point light sources. The original signal is stronger and greatly improved. Recognition efficiency of particulate matter. At the same time, constant power control is adopted for the light source to ensure the stable output of the original signal and the stability of the measurement.

Finally, a dehumidification device is equipped to prevent small water droplets in the outdoor environment from entering the detection gas chamber, and eliminate the impact of water vapor on the accuracy of the dust sensor.

As a result, Cubic has realized the full coverage of dust detection application from indoor to car, and then to outdoor. Our biggest advantage is that it can combine the requirements of different field application scenarios for products, realize the flexible configuration of technology, and provide creative and high-quality solutions for customers. In the future we could help customer product upgrades, and provide further technology support.

About Cubic

Cubic was established in 2003 in "Wuhan-Optics Valley, China". It is a high-tech enterprise specializing in R&D, production and sales of gas sensors and gas analysis instruments. Xiong Youhui, chairman and founder of Cubic Sensor and Instrument Co., Ltd, is a PhD in thermal engineering from Huazhong University of Science and Technology, a professor-level senior engineer, and an expert with special allowances from the State Council.

Cubic has developed gas transmission based on the principles of non-dispersive infrared (NDIR), light scattering detection (LSD), ultrasonic (Ultrasonic), ultraviolet differential absorption spectroscopy (UV-DOAS), thermal conductivity (TCD), laser Raman (LRD), etc. The sensor technology platform has formed two major types of industrial ecology, gas sensors and gas analysis instruments, and dozens of different products, which are widely used in home appliances, automobiles, medical treatment, environmental protection, industry, energy measurement and other fields at home and abroad.

Cubic is the first batch of intellectual property demonstration construction enterprises in Hubei Province. It has established the Hubei Province Gas Analysis Instrumentation Engineering Technology Research Center and the Hubei Province Enterprise Technology Center. It has undertaken the national major scientific instrument and equipment development special projects, the Ministry of Industry and Information Technology Internet of Things development special projects and other national technologies Development project. As of the end of August 2020, the company and its subsidiaries have 101 domestic and foreign registered patents, including 99 domestic and 2 foreign patents. There are 33 invention patents (31 domestically, 2 overseas). The company and its subsidiary Hubei are determined to be selected as a demonstration enterprise for the “one-stop” application plan of industrial strong base sensors by the Ministry of Industry and Information Technology in 2019. With long-term technological accumulation, good product performance and international vision, the company has obtained the recognition of many well-known domestic and foreign companies, and the products are sold throughout the country and exported to many countries and regions.